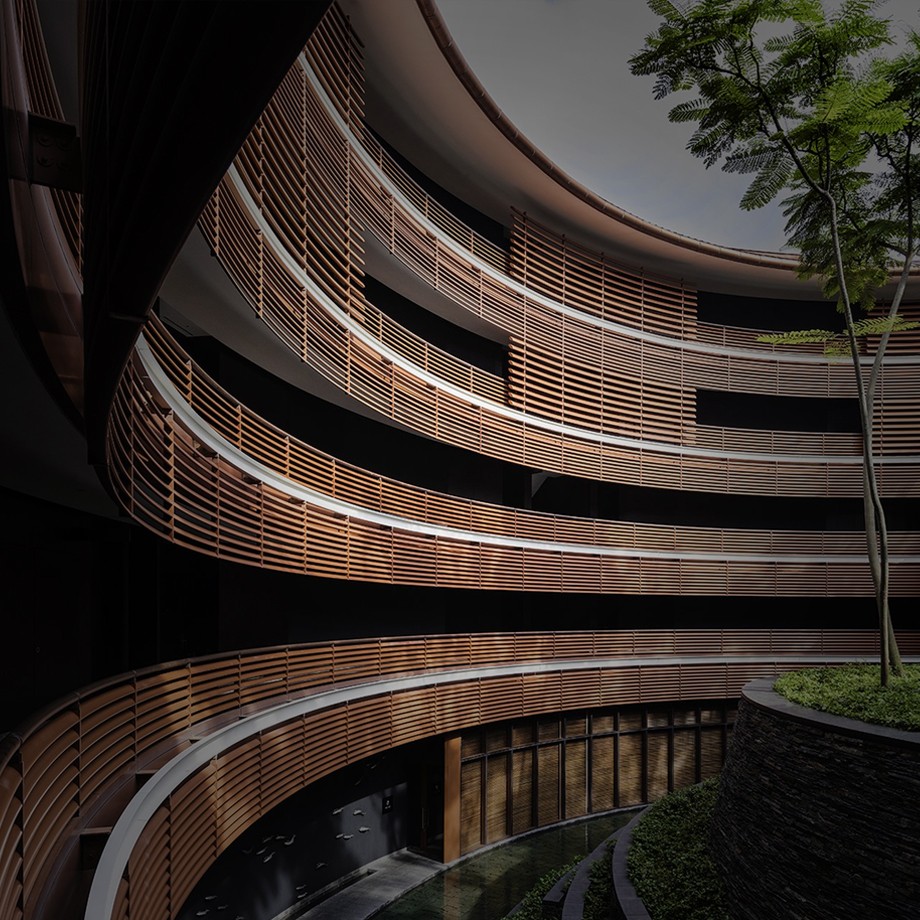

The Capella Hotel in Singapore is a luxury hotel located in Singapore.Guests can experience the best hotel stay in Singapore. Situated on Sentosa Island, the Capella Hotel features 112 rooms, including suites, villas, and manors.Guests can fully enjoy a privat···

Capella Hotel

Hotel / 20000㎡

We will call you back on working days, please stay tunedThe Capella Hotel in Singapore is a luxury hotel located in Singapore.

Guests can experience the best hotel stay in Singapore. Situated on Sentosa Island, the Capella Hotel features 112 rooms, including suites, villas, and manors.

Guests can fully enjoy a private accommodation experience amidst the stunning natural surroundings.

Behind the exquisite project lies the dedicated craftsmanship of the project team.

They overcame challenges and meticulously crafted the "Happy Space" together.

The project demands extremely high construction precision and quality.

To maximize the project's effect and create a Southeast Asian decorative style, the decoration team used a total station for 3D positioning and layout.

This method allowed for precise arrangement of construction points and angles.

With the aid of technology, the team consistently set the stage for high-quality construction.

During the hotel construction process, which involved multiple room types, the project team opted for Building Information Modeling (BIM).

Throughout the construction, the team used BIM to detect and avoid clashes between mechanical, electrical, and plumbing (MEP) systems.

Additionally, they implemented on-site mock-ups to verify the accuracy of the BIM model, continuously optimizing and adjusting it as needed.

This approach significantly ensured precision control during the installation process, allowing both engineering quality and decorative style to excel simultaneously.

To ensure the construction timeline and accelerate material production, the project team conducted an in-depth analysis of the drawings and material processing cycles.

They identified the fixed and variable relationships of different spaces and materials to place bulk orders, thereby ensuring processing efficiency.

After controlling installation precision through segmented construction, they implemented collision prevention barriers and anti-pollution film protection measures.

These steps ensured the hotel's project was completed successfully on the first attempt.

After the official acceptance of the project model rooms, the decoration team operated like a "precision machine," running smoothly, accurately, and efficiently.

During the construction process, the project used model construction as a guide, completing material sampling and sealing in advance.

They followed a plan-centric approach, formulating detailed construction schedules ahead of time and coordinating the sequencing of tasks effectively.

Regarding the pursuit of high standards and high quality, the project leader said, "The decoration team spares no effort on each milestone.

Detailed finishing work is optimized in advance through coordination with design and other units. During construction, on-site technical clarifications are conducted, and only after passing inspection can large-scale construction proceed.”

If you have questions or want to know more about our work, please fill in the form, and we will reply within 24 hours.